Custom Plastic Extrusion Manufacturers Things To Know Before You Buy

Wiki Article

Some Known Details About Custom Plastic Extrusions

Table of ContentsThe 9-Minute Rule for Extrusion Of PlasticsThe 8-Minute Rule for Custom Plastic ExtrusionsSome Known Incorrect Statements About Plastic Extrusion Companies Little Known Facts About Custom Plastic Extrusions.6 Easy Facts About Plastic Extruded Profiles Shown

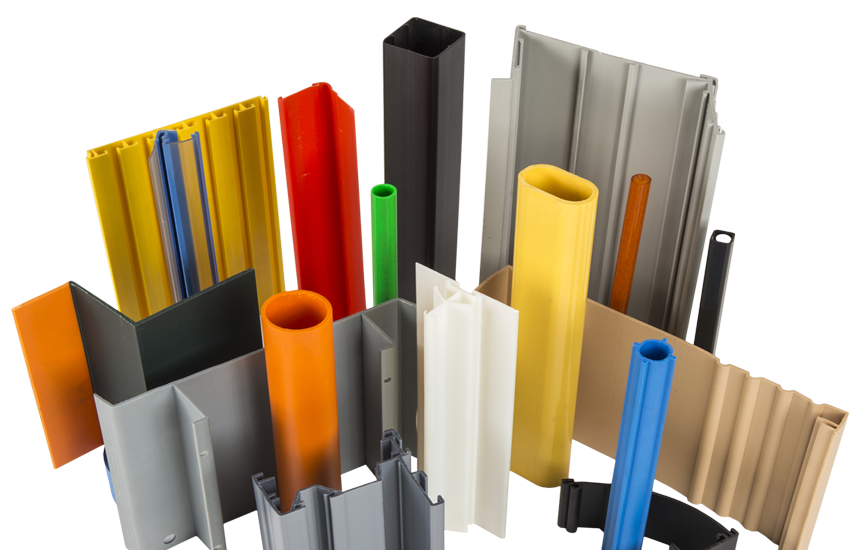

At Vip, we have decades of experience production countless one-of-a-kind personalized plastic extrusions in virtually every form, size, and also color you can imagine - https://keller-plastics.jimdosite.com/. Our specialized lies in making plastic accounts especially for a particular application. You inform us what you require as well as we will manufacture it, meeting the highest possible high quality requirements.From pre-prototype to post-production, ACE has the capability and innovation to do everything. We serve large and tiny firms in industries varying from vehicle to clinical, with hard material requirements to limited resistances in America, copyright, Mexico, and also Europe. No matter where you are or what industry you represent, you can depend on ACE for tailored solution and customer fulfillment.

That implies quick quote service or material suggestion is just a phone call away. Your inquiries are always answered promptly by our experienced solution team, and you obtain the assistance you require with no delays or complication.

What Does Plastic Extrusion Manufacturers Do?

With over 100 consolidated years of experience in plastic extrusion, GSH Industries is a leading B2B supplier of custom-made plastic extrusions, tubes, and plastic profiles in North Ohio. Our designers as well as engineers can help you in picking the very best materials for your line of product - http://gogs.kaas.kit.edu/k3ll3rpl4st8. We have a vast selection of plastic materials as well as can match any kind of custom-made shades to your client's specs - plastic extruded profiles.It is among the most preferred methods plastic parts are currently generated because of its flexibility. Personalized extrusions can be developed into complex forms of varying thicknesses, toughness, sizes, shades, and also appearances, and are fairly very easy to collaborate with. The extrusions can likewise be created with efficiency enhancing qualities such as fire resistance, boosted toughness, boosted strength, anti-friction or anti-static properties, and also much more.

It can likewise potentially bring about longer cooling time with will certainly increase your general manufacturing time as well as costs. Sharp corners and notches produce weak factors in the account where breaking or failing can happen because they reduce the effect resistance of the account by developing a high stress concentration. Preferably, when creating your account extrusion sharp edges need to be stayed clear of completely instead go for rounded edges.

What Does Custom Plastic Extrusion Manufacturers Do?

Preferably the span should be equal to the wall surface thickness of the extrusion. This adds to smoother product circulation throughout extrusion and much less stress on the profile's corners. They call for added alterations to the die to make sure correct product circulation, can create irregular cooling, as well as can trigger areas of weakness that might result in failure.If your component has to have hollows, a hollow within an additional hollow is never ever an excellent suggestion. It will certainly be dislodged of shape before the extrusion solidifies - https://sco.lt/7V4e0m. If your extrusion needs features such as legs, grooves, snap-ins, or other things inside of the extrusion it is best to make an easily obtainable opening into the extrusion to ensure that you can much better integrate those attributes.

Plastic Extrusion Companies for Dummies

Understanding some consumers might be not familiar with our plastic account extrusion capabilities, we have compiled a checklist of questions we are frequently asked. Durometer is a measurement of the product's hardness and is gauged with a gadget which is pressed against the account's surface, resulting in a dial guage analysis.

Usual ranges are Shore A for adaptable products and Coast D for rigid substances. Double durometer, or co-extrusion, is the combination of two or more materials of differing physical residential or commercial properties into a solitary extruded piece. An instance would certainly be an inflexible get rid of adaptable fingers that can be made use of as a gasket or cushion.

Depending on the part complexity as well as raw materials, one can approximate the prices beginning at less than $1,000. Due to varying set up prices and also run efficiencies, we attempt to limit the minimum manufacturing amount to 1,000 lineal feet.

An Unbiased View of Custom Extrusion Manufacturer

First, what creates the line. If you take a close check out a drawing for a plastic profile with a crossway leg, you will certainly see there is more mass in the location of the crossway. Since thermoplastic products diminish some throughout the cooling procedure, the crossway of 2 legs cools at a slower rate than the remainder of the profile, triggering it to reduce more due to the mass of the account.

A device developer would usually separate the flow of the 2 legs within the die, and allow them to find back with each other as the extrudate is being compressed to the front of the extrusion die. This can in many cases produce a weld line where the 2 thaw streams are revived together so careful tuning of the extrusion tooling is crucial to decrease this line.

Report this wiki page